ProfessionalFry Pan Manufacturerin China

16+ Years

Manufacturing Excellence in Premium Stainless Steel Cookware

50,000+

Fry Pan Units Monthly Production Capacity

ISO Certified

ISO 9001, FDA, and LFGB Certified Stainless Steel Kitchenware

Global Reach

Serving 50+ Countries with Wholesale Stainless Steel Cookware

If you’re planning to import stainless steel fry pans from China or searching for a trusted OEM cookware supplier, you’re in the right place. This page was designed specifically for cookware buyers like you—whether you’re a wholesaler, supermarket buyer, brand owner, or sourcing agent.

To help you evaluate the right supplier and make better purchasing decisions, we’ve structured this page to cover every essential topic. From technical specifications to industry insights, customization capabilities, and real success stories—everything you need is just a scroll away.

Whether you’re comparing fry pan factories, preparing a private label cookware project, or sourcing for large-volume procurement, the following sections will help you navigate with confidence.

General Applications of Fry pans and Skillets

Bonray stainless steel fry pans are widely used in retail, hospitality, and foodservice sectors. Ideal for supermarket shelves, private label cookware brands, commercial kitchens, and e-commerce sales, they offer reliable performance and customizable options. Designed for induction, gas, and electric stovetops, our fry pans meet the needs of importers, wholesalers, distributors, and brand owners seeking durable, market-ready cookware solutions.

Key Features That Define Our Frying Pans

Premium Stainless Steel Construction

Our Best-Selling Fry Pans & Skillets– Ready for Your Market

Explore our most in-demand stainless steel fry pans—trusted by global buyers for quality, durability, and flexible customization. Each model is built to meet the needs of retail chains, kitchenware distributors, and private label brands.

Copper Plated Tri-ply Stainless Steel Fry Pan with Steel Lid

- Stainless Steel Lid – Strong and Durable

- Tri-Ply Full Clad Stainless Steel Construction – Durable and Efficient

- Multi-Cooktop Compatibility – Versatile and Convenient

- Food Safety Certified – Trusted for Safe Cooking

- Riveted Stainless Steel Handles – Secure and Reliable

Tri-ply Stainless Steel Skillet with Steel Lid

- Tri-Ply Full Clad Stainless Steel Construction – Durable and Efficient

- Multi-Cooktop Compatibility – Versatile and Convenient

- Precision Cast Stainless Steel Handles – Heat Resistance

- Food Safety Certified – Safe and Reliable

- Custom Branding and Design Options for Bulk Buyers

Tri-Ply Stainless Steel Frying Pan with Honeycomb Etched Surface

- Tri-Ply Stainless Steel Construction – Even Heat Distribution

- Various Size – Perfect for Versatile Cooking

- Ergonomic Stainless Steel Handles – Safe and Comfortable Grip

- Honeycomb Etched Surface - Ensure durability and easy release.

- Multi-Cooktop Compatibility – Maximum Versatility

- Durable and Food-Safe Materials

- Custom Branding and Design Solutions for Bulk Buyers

Hammered Tri-ply Stainless Steel Nonstick Frying Pan

- Tri-Ply Stainless Steel Construction – Fast, Even Heat Distribution

- Multiple Sizes for Versatile Cooking Needs

- Ergonomic Stainless Steel Handles – Secure and Comfortable Grip

- Nonstick Coating Surface - Easy release and cleaning

- Multi-Cooktop Compatibility – Flexible for Any Kitchen

- Food Safety Certified – Safe for Professional and Home Use

- Custom Branding and Design Solutions for Bulk Buyers

Want to Explore Our Full Range of Products?

Customization Options

Customize Your Frying Pans From a Reliable Manufacturer

With extensive manufacturing capabilities and a focus on quality, Bonray ensures your customized frying pans align with your market demands, helping you reduce costs, enhance product appeal, and improve customer satisfaction.

Branding Solutions for Enhanced Market Appeal

Your cookware’s branding is key to standing out in retail stores and professional kitchens. Bonray offers flexible logo integration options, including:

- Stamping – Ideal for bold and permanent logo designs.

- Laser Engraving – A clean and precise marking method for premium branding.

- Electrochemical Etching – Suitable for durable and professional-looking logos.

These methods ensure your brand stands out while maintaining a polished and professional appearance.

Versatile Construction Options for Cooking Efficiency

Bonray offers multiple construction designs to meet your performance requirements and budget:

- Multi-Ply Full Clad Stainless Steel Construction – Provides even heat distribution from base to rim for optimal cooking results.

- Composite Induction Bottom – Designed for fast and efficient heat conduction, compatible with all cooktops including induction.

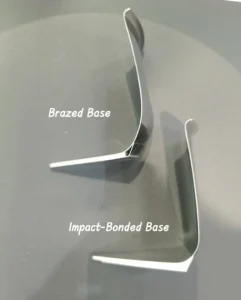

Our composite induction bottom options include Brazed Base which is a cost-effective solution and Impact-Bonded Base which ensures a strong, seamless bond between layers for enhanced durability.

For heat core materials we also have two options: Aluminum Core and Copper Core, offering superior heat conductivity for precise temperature control.

Material Choices for Durability and Cost Control

To support your budget and quality requirements, Bonray offers:

- 304 Stainless Steel – Excellent corrosion resistance, ideal for premium cookware lines.

- 201 Stainless Steel – A more economical alternative with solid durability for budget-conscious markets.

Material thickness can be adjusted based on your performance goals and cost considerations.

Lid Customization for Enhanced Cooking Control

Bonray offers a variety of lid options to improve cooking efficiency and meet user preferences:

- Stainless Steel Lids: Durable and ideal for professional kitchens where breakage resistance is essential.

- Tempered Glass Lids: Allow users to monitor cooking progress without lifting the lid, reducing heat loss and improving energy efficiency.

- Vented Lids: Designed to control steam release and prevent boil-overs in commercial kitchens.

Each lid can be customized with logo engraving, custom handle designs, or specialized rim finishes.

Handle Design for Safety and Comfort

Our cookware products feature multiple handle options designed for improved strength, safety, and comfort:

- Riveted Handles: Provide maximum stability and long-term durability.

- Welded Handles: Offer a smooth, seamless design for added strength and easy cleaning.

- Ergonomic Handles: Shaped for improved grip and user comfort, reducing hand fatigue.

- Heat-Resistant Handles: Stay cool during cooking to enhance safety in busy kitchens.

Custom Packaging Solutions for Retail and Wholesale

Our flexible packaging solutions are designed to support various sales channels:

- Retail-Ready Boxes: Ideal for supermarket shelves and retail displays.

- Branded Gift Sets: Designed for promotional campaigns and seasonal product lines.

- Bulk Protective Packaging: Provides enhanced protection for large orders during shipping and storage.

Custom packaging can be tailored with logo printing, product descriptions, and care instructions to improve your product’s retail appeal.

Estimated Cost Analysis For Stainless Steel Frying Pans

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a 40 ft container of cookware sets :

Some countries require imported products to undergo inspection and testing to ensure that they meet certain safety and quality standards.

$5,000

Shipping costs can vary depending on the size and weight of the shipment, as well as the shipping method used. Take the US as an example, the sea freight for a 40'HQ costs about $4000.

$4,300

When importing goods from China, you may be subject to customs duties and taxes. The amount of duties and taxes vary depending on the country of import and the value of the shipment. It's important to research the duties and taxes applicable to your specific country of import to ensure that you are aware of the additional costs involved.

10% of the invoice amountEfficientCookwareProduction Schedule

At Bonray, we understand that timely delivery is crucial for your business. Our efficient cookware production schedule is designed to ensure your orders are manufactured, inspected, and shipped on time — without compromising quality.

With streamlined processes, advanced machinery, and experienced technicians, we optimize every stage of production to meet your deadlines. Whether you’re placing a trial order or managing large-scale production, we prioritize efficiency to help you maintain inventory flow and meet customer demand.

Trust Bonray to deliver reliable stainless steel skillets — on time, every time.

Step 1: Material Preparation (3-7 days)

Material Cutting: Raw stainless steel sheets are cut to the required size using cutting machines to ensure precision of the stainless steel cookware.

Step 2: Cookware Body Process (8-10 days)

- Rolling: The cut material is rolled into a cylindrical cookware shape.

- Seam Welding: The vertical seam is securely welded for durability.

- Seam Flattening: The welded seam is pressed to ensure a smooth, even surface.

- Seam Grinding: The seam is carefully polished for a seamless finish.

- Body Shaping: The cylinder is adjusted to ensure perfect roundness.

- Edge Trimming: The top edge is shaped and flanged for added strength and aesthetics.

Step 3: Cookware Base Process (10-15 day)

- Deep Drawing: Stainless steel is drawn into the desired base shape.

- Aluminum Core Bonding: Using friction welding, an aluminum core or copper disc is bonded between stainless steel layers to create a 3-ply or 5-ply clad bottom for superior heat distribution.

- Edge Cutting and Shaping: The base is trimmed and shaped for a clean finish.

- Base Polishing: The inner and outer base surfaces are polished for a smooth, professional look.

Step 4: Assembly Process (10-12 days)

- Seam Welding: The cookware pot or pan body and base are welded together using a durable circular seam weld.

- Seam Pressing: The welded seam is pressed for reinforcement, ensuring no leaks (tested with a water-tightness check).

- Seam Polishing: Both the inner and outer seams are carefully polished to ensure a smooth surface.

- Sanding Finish: The entire cookware pot or pan is sanded to achieve a uniform texture.

Step 5: Cookware Handle Process (5 days)

- Handle Plate Stamping: Handle plates are stamped from stainless steel sheets.

- Wire Stamping: Stainless steel wire is stamped and shaped to form durable handles.

- Handle Welding: The handle plate and wire are securely welded together.

- Handle Installation: The completed handles are riveted onto the cookware pot or pan body for firm attachment.

Step 6: Cookware Lid Process (4 days)

- Deep Drawing: Stainless steel sheets are drawn into the desired lid shape.

- Edge Trimming: The lid edges are cut and shaped for a clean finish.

- Cleaning: Lids are thoroughly cleaned to remove dust and debris.

- Sanding Finish: The interior and exterior of the lid are polished for a smooth surface.

- Lid Handle Welding: The lid handle is securely welded in place.

Step 7: Final Assembly Process and Packaging (3-5 days)

- Inspection: Each finished cookware product undergoes a detailed quality check to ensure no defects.

- Cleaning: Products are cleaned to maintain a flawless finish.

- Packaging: Cookware products are carefully packed to prevent damage during transport.

Rigorous Quality Assurance — Ensuring Reliability in Every Cookware Set

Every Bonray stainless steel cookware set undergoes strict quality checks to meet international standards. From material selection to final inspection, we ensure your cookware products are durable, safe, and built to perform — giving you confidence with every order.

Industry insights

What B2B Buyers Must Know Before Sourcing Fry Pans from China

If you’re sourcing cookware at scale, you already know: price is only one part of the equation. For importers, distributors, and private label brands, success depends on partnering with a fry pan supplier who can deliver consistent quality, reliable timelines, and true customization capabilities.

At Bonray, we’ve worked with over 300 clients across 30+ countries—and we’ve seen the same issues repeatedly derail cookware procurement projects. Here’s what to watch for—and how we help you avoid them.

1. Material Grades: What 201 vs. 304 Stainless Steel Means

Not all stainless steel is created equal.

✅ 304 Stainless Steel (High-Grade Option)

Higher corrosion resistance, better food safety profile. Ideal for premium lines, wet cooking, and international markets (EU/US).

✅ 201 Stainless Steel (Budget-Friendly Option)

Lower nickel content, lower cost, less corrosion resistance. Best for budget lines or dry-heat use.

Buyer Tip: If you’re selling into high-end markets or offering warranties, use 304 SS to avoid returns and maintain trust.

Aluminum Core vs Copper Core Frying Pan

✅ Aluminum Core:

Provides fast, even heat distribution at a lower cost.

Lightweight design improves ease of use in home kitchens.

Common in tri-ply full clad cookware for balanced performance.

✅ Copper Core:

Offers superior heat conductivity for precise temperature control.

Common in high-end cookware sets designed for professional chefs.

More expensive but ideal for cookware that requires fast, responsive heat control.

Tip for Buyers: For general retail markets, an aluminum core balances performance and cost. For professional chefs or specialty cookware lines, copper core skillets provide enhanced precision.

Nonstick Coatings vs Stainless Steel Interiors

✅ Nonstick Coatings:

Ideal for easy-release cooking with minimal oil, perfect for health-conscious consumers.

Suitable for delicate foods like eggs and pancakes.

Best suited for frying pans aimed at home cooks.

✅ Stainless Steel Interiors:

Highly durable and scratch-resistant for long-term use.

Preferred by professional chefs for browning, searing, and deglazing.

Ideal for cookware sets marketed to hotels, restaurants, and commercial kitchens.

2. Cookware Construction and Performance: What Makes a Difference?

Construction affects how efficiently cookware heats, retains warmth, and withstands long-term use. Understanding these differences helps you choose cookware that meets your customers’ expectations.

Tri-Ply Full Clad Fry Pan (Premium Choice)

Features layers of stainless steel, aluminum, or copper bonded throughout the pot’s body.

Provides even heat distribution from the base to the walls, improving cooking performance.

Reduces hot spots and ensures precise temperature control.

Best For: Premium cookware lines, professional chefs, and customers who prioritize quality.

Encapsulated Bottom (Sandwich Bottom) Fry Pan (Cost-Effective Choice)

Features a layered base with a conductive core bonded to the bottom of the pot or pan.

Provides solid heat distribution and improved induction compatibility.

More affordable than tri-ply cookware.

Best For: Entry-level cookware sets, budget-conscious markets, and general retail buyers.

Brazed Base vs Impact-Bonded Base

✅ Brazed Base:

- A cost-effective option that provides solid heat distribution.

- Suitable for standard cookware sets marketed to everyday home cooks.

✅ Impact-Bonded Base:

More durable and long-lasting than brazed bases.

Preferred for cookware sets designed for professional kitchens or frequent use.

Tip for Buyers: Choose impact-bonded cookware sets for high-performance cookware lines, and brazed base cookware for budget-conscious retail offerings.

3. Key Design Features That Improve Functionality

Your fry pans’ design directly affects user experience and customer satisfaction. Add value to your cookware product line with custom options like:

✅ Handle Technology: Welded or Riveted

Welded Handle: Clean look, easier to clean, lower production cost

Riveted Handle: More durable, popular in professional kitchens, but harder to clean around rivets

Buyer Tip: Riveted handles are preferred in Western markets for their durability. If you’re targeting Asia or online sales, welded handles with minimal seams may be better for aesthetics.

✅ Logo Options

- Logo engraving (e.g., laser-engraved, etched, or embossed designs).

- Custom surface finishes to match your branding.

- Tailored packaging for enhanced retail presentation.

✅ Surface Finish: Mirror, Satin, Brushed, or Sandblasted:

Mirror Polish: Premium appearance, reflects light well in retail, but fingerprints show easily

Brushed/Satin Finish: Matte texture hides marks, looks modern, widely accepted in both retail and commercial markets

Sandblasted/Stone Texture: Non-slip, rugged look, used in commercial kitchens

Buyer Tip: Match your surface finish to your end user: mirror for display value, brushed for practical use, sandblasted for commercial applications.

✅ Thickness & Weight: The Silent Quality Marker:

A pan that looks great but warps after a few uses? That’s usually due to poor thickness.

0.5–0.6mm: Entry-level, price-sensitive

0.7–0.8mm: Standard retail or gift-grade, usually for single-ply construction

2.2mm and above: Premium quality, commercial-grade durability usually for tri-ply construction

Buyer Tip: Always confirm body thickness (not just weight) before placing an order. It directly impacts performance and perceived value.

4. Certifications for Safety and Compliance

Choosing cookware that meets food safety standards ensures product quality and minimizes liability risks.

✅ FDA Approved: Ensures materials are safe for food contact under US regulations.

✅ LFGB Certified: Demonstrates compliance with European food safety standards.

✅ ISO Certification: Confirms the manufacturer’s adherence to international quality control processes.

Tip for Buyers: When purchasing cookware for export to the US, Europe, or Japan, prioritize certified cookware to ensure product compliance.

Case Study: From Concept to Shelf – Fry Pan Brand Success Story

Client Profile:

A mid-sized kitchenware brand based in Western Europe was preparing to launch a new private label stainless steel fry pan set targeted at both retail stores and e-commerce platforms. The client’s goal was to develop a 2-piece fry pan set with 24cm and 28cm sizes that would meet European food safety standards, offer premium durability, and be induction-compatible. Their previous suppliers—two different OEM fry pan manufacturers in China—had caused serious delays and inconsistent product quality, including loose handle fittings and low-quality nonstick coating problems. Facing tight launch deadlines, they turned to Bonray Cookware for a more reliable and professional manufacturing solution.

Bonray’s Solution:

When our team received the inquiry, we began by analyzing the client’s existing product pain points. We then proposed a complete OEM solution tailored to their requirements. Bonray’s engineers refined the product design to ensure the fry pans would perform well on induction cooktops and meet the durability standards expected in Western European retail markets. The pans were produced using high-grade 304 stainless steel with a mirror-polished finish, riveted handles for added strength, and tri-ply all-clad stainless steel for fast and even heat distribution. The client’s custom logo was laser-etched on both the pan base and the handle, reinforcing their brand identity across all sales channels.

In addition to product manufacturing, Bonray also supported the client with packaging development. Our team designed a full-color gift box with barcode, usage icons, and a folded instruction manual in multiple languages—all compliant with EU shelf display regulations.

Production of the 5,000-unit order was completed in just 35 days at our stainless steel cookware factory in Guangdong, and the shipment was successfully exported via FOB Shenzhen. The new private label fry pan set launched across six European countries. It sold out within six weeks of arrival, outperforming the client’s previous OEM product line with a 25% increase in positive customer reviews. Based on the strong performance and smooth collaboration, the brand signed a two-year supply agreement with Bonray for continued development of stainless steel cookware products, including sauce pans and stockpots.

This success story reflects what Bonray delivers as a custom stainless steel fry pan manufacturer: end-to-end OEM support, fast lead times, consistent product quality, and real partnership that extends beyond a single transaction.

Bonray is a reliable stainless steel cookware manufacturer with proven expertise in cookware production. Businesses worldwide trust us because we offer:

With over 15 years of manufacturing experience, Bonray has delivered 100+ customized stainless steel cookware solutions to bulk buyers worldwide. Our 98% on-time delivery rate, flexible MOQs, and market-driven designs ensure you get cookware solutions that meet your business needs. Supported by our 24/7 professional team, we’re committed to providing the best stainless steel cookware with reliability you can trust.

- Over 100 Custom Cookware Solutions

- 15+ Years of Manufacturing Expertise

- 98% On-Time Delivery Rate

- Flexible MOQ for Bulk Buyers

- 24/7 Professional Support

The FAQs About Fry Pans & Skillets

If you’re exploring options to import or customize stainless steel fry pans in bulk, this FAQ section answers the most common questions asked by B2B buyers, distributors, and private label brands. Each answer is written to be clear, concise, and optimized for quick understanding—and search engine visibility.

304 stainless steel is the best option for fry pans due to its superior corrosion resistance, food safety compliance, and durability in both home and commercial kitchens.

Tri-ply cookware combines stainless steel with an aluminum or copper core, ensuring fast, even heat distribution without hot spots.

Yes. Tri-ply cookware offers better heat conductivity, durability, and cooking performance, making it ideal for professional kitchens and premium cookware lines.

201 stainless steel is more cost-effective but less corrosion-resistant. 304 stainless steel is more durable, safer for acidic foods, and preferred for export markets like the US and EU.

"Fully clad" refers to cookware constructed with layers of different metals throughout the pot or pan, ensuring even heat distribution and eliminating hot spots.

Higher ply construction, such as 3-ply or 5-ply, enhances durability and heat distribution. For example, 5-ply cookware offers superior heat retention and even cooking.

Impact-bonded bases are stronger and more durable, ideal for commercial kitchens. Brazed bases are more affordable and suitable for everyday home use.

Yes, we provide customization options, including adding your brand's logo to our products.

Absolutely. We offer custom handle options, including riveted stainless steel wire handles, welded handles, and ergonomic designs to improve durability and functionality for professional and home kitchens.

Yes, we provide custom sizes, surface finishes (e.g., polished, brushed), and logo options like laser engraving, etching, and embossing.

Our minimum order quantity typically starts from 500 to 1,000 units per model, depending on design complexity and customization requirements.

Yes, we offer samples for quality evaluation and design confirmation. Sample fees may apply but can be refunded after bulk order confirmation.

We provide color boxes, sleeves, hang tags, gift boxes, and shrink-wrapping. All packaging can be customized with your logo, barcode, and local labeling requirements.

An encapsulated bottom features a layer of aluminum sandwiched between stainless steel. It improves heat conductivity and ensures compatibility with induction stoves.

Stainless steel cookware is durable and ideal for searing, browning, and high-heat cooking. Nonstick cookware requires less oil and is easier to clean but may wear down faster.

Yes, most of our stainless steel fry pans are induction-compatible, using magnetic stainless steel in the base to ensure fast, even heating on all stovetops.

While our standard models are stainless steel surface, we can apply PFOA-free non-stick coatings upon request, including ceramic or PTFE options.

Yes. We offer various surface treatments such as mirror polish, brushed (satin), and sandblasted finishes to suit your market positioning.

Absolutely. We can support your entire private label project, from product development and design to custom packaging and documentation.

We conduct raw material checks, in-line inspections, and final batch AQL inspections. Our products are tested for coating adhesion, dimensional accuracy, and safety compliance.

Standard production lead time is 30 to 45 days after sample approval. Urgent or repeat orders can be processed faster depending on factory capacity.

Yes. Our engineering team supports new product development (ODM) with 2D/3D drawings, prototyping, and mold fabrication for unique designs.

Yes. Mixed sizes within the same product line are allowed to meet your assortment needs, especially for retailers and promotional bundles.

Our cookware sets undergo strict material inspection, weld testing, and polishing checks to meet international standards like FDA, LFGB, and ISO.

We manage both FOB and CIF shipments and can arrange delivery to your preferred port or warehouse.

Simply click "Get a Custom Quote" or "Contact Our Sales Team" for prompt assistance.

We usually accept T/T (30% deposit, 70% before shipment). For long-term clients or large-volume buyers, we can discuss flexible terms.

The Basic Knowledge About Stainless Steel Cookware

Ready to Elevate Your Cookware Collection?

Tell us your requirements, and our team will provide a tailored solution that fits your business goals.

Complete Your Professional Cookware Collection

Comprehensive set including sauce pans, stock pots, and frying pans for commercial kitchens

Available in 6-20 quart capacities for large-batch cooking in professional settings

Straight-sided pans for sautéing, simmering, and deglazing, optimized for consistent heat and controlled cooking.

Wide and deep cookware with dual handles, suitable for stews, braising, and slow cooking in volume meal prep environments.