Wholesale Stainless Steel Griddles & Grill Pans with OEM/ODM Solutions

Welcome to Bonray Cookware, a leading kitchenware manufacturer and cookware supplier in China, specializing in stainless steel griddles and grill pans for B2B customers worldwide.

We combine advanced manufacturing, a vertically integrated supply chain, and tailored OEM/ODM services to deliver durable, commercial-grade products that meet strict international standards.

16+ Years

Manufacturing Excellence in Premium Stainless Steel Cookware

10,000+

Grill Pan Units Monthly Production Capacity

ISO Certified

ISO 9001, FDA, and LFGB Certified Stainless Steel Kitchenware

Global Reach

Serving 50+ Countries with Wholesale Stainless Steel Cookware

In this section, you’ll find a complete roadmap covering every aspect of griddles and grill pans for high-volume buyers.

To simplify your search, we’ve organized a detailed content directory for quick access to product specifications, customization options, and bulk order details.

Click on any link to learn more about the complex world of kitchenware manufacturing—from understanding product specifications to optimizing procurement and logistics with a trusted cookware factory.

General Applications of Griddles and Grill Pans

Our griddles and grill pans serve as multi-purpose cooking tools for diverse professional needs. From sizzling steaks and burgers to searing vegetables and sandwiches, these products streamline meal preparation in restaurants, catering venues, and large-scale kitchens. Partnering with a reputable kitchenware manufacturer ensures you have the reliable, high-performance cookware necessary to maintain efficiency and quality in every dish. As a trusted cookware factory, we focus on crafting durable, easy-to-maintain solutions that drive productivity and profitability for all types of foodservice operations.

Key Features That Define Our Griddles & Grill Pans

Heavy-Gauge Steel Construction

Easily Maintained Surface Coating

Our Best-Selling Griddles & Grill Pans

Below are our most popular griddle and grill pan models, each designed to meet the rigorous standards of importers, wholesalers, retailers, supermarket buyers, brand owners, and distributors. As a dedicated kitchenware manufacturer and cookware supplier, we ensure consistent quality, reliable performance, and flexible customization to align with your brand requirements.

24cm Cast Iron Steak Grill Pan

- Built from heavy-gauge cast iron, delivering superb heat retention and unmatched durability in busy kitchens.

- Pre-seasoned surface ensures natural nonstick cooking, significantly reducing oil usage and enhancing food flavor seamlessly.

- Ergonomic handle design promotes secure gripping, preventing slips while transferring heavy pans in commercial kitchens.

- Optimized shape supports uniform heat distribution, eliminating hot spots and ensuring consistently perfect searing results.

- Customizable design allows choosing handles, sizes, or logos, reinforcing brand identity through unique details.

Heavy-Duty Cast Iron Reversible Griddle

- Made from seasoned cast iron, it resists rust while maintaining an all-natural, chemical-free cooking surface.

- Reversible ribbed design offers dual surfaces, enhancing cooking versatility and delivering consistently impressive grill marks.

- Integrated side handles ensure safe lifting, supporting easy transportation in fast-paced commercial kitchen environments worldwide.

- Even heat distribution reduces hot spots, promoting faster cooking and preserving flavors for larger batches.

- Minimal surface maintenance saves time, ensuring effortless cleanup and prolonging product lifespan in busy environments.

| Description | Size (cm) | Weight (KG) | Suface Treatment |

|---|---|---|---|

| Cast Iron Griddle | 20*40*1.5 | 2.6 | Oil Pre-seasoned |

| Cast Iron Griddle | 23*45*1.5 | 3.1 | Oil Pre-seasoned |

| Cast Iron Griddle | 24*50*1.5 | 3.6 | Oil Pre-seasoned |

Stainless Steel Two-in-one Griddle with Wooden Handle for Outdoor Grill

- Constructed from robust 430 stainless steel, ensuring direct food contact safety and extended product lifespan.

- Widened dual handles ensure stable grip, preventing slips while comfortably supporting heavier loads during transport.

- Uniformly distributed mesh vents improve heat conduction, guaranteeing consistent cooking results and reduced hot spots.

- Customized logo, handles available

29cm Stainless Steel Square Grill Pan with Beech Wood Handle

- Premium 304 Stainless Steel: Corrosion-resistant, food-safe material that supports long-term commercial use.

- Tri-Ply Construction: Layers of steel and aluminum for enhanced heat conductivity and consistent cooking results.

- Multi-Purpose Design: Square shape and flat bottom are ideal for searing, frying, and sautéing.

- Beech Wood Handle: Natural hardwood handle offers a secure grip and modern aesthetic appeal.

- Mail-Order Packaging: Arrives securely packed in a postage box for safe and efficient shipping.

- Custom Branding and Design Solutions for Bulk Buyers

Want to Explore Our Full Range of Products?

Customization Options

Customize Your Cookware From a Reliable Manufacturer

With extensive manufacturing capabilities and a focus on quality, Bonray ensures your customized cookware align with your market demands, helping you reduce costs, enhance product appeal, and improve customer satisfaction.

Branding Solutions for Enhanced Market Appeal

Your cookware’s branding is key to standing out in retail stores and professional kitchens. Bonray offers flexible logo integration options, including:

- Stamping – Ideal for bold and permanent logo designs.

- Laser Engraving – A clean and precise marking method for premium branding.

- Electrochemical Etching – Suitable for durable and professional-looking logos.

These methods ensure your brand stands out while maintaining a polished and professional appearance.

Versatile Construction Options for Cooking Efficiency

Bonray offers multiple construction designs to meet your performance requirements and budget:

- Multi-Ply Full Clad Stainless Steel Construction – Provides even heat distribution from base to rim for optimal cooking results.

- Composite Induction Bottom – Designed for fast and efficient heat conduction, compatible with all cooktops including induction.

Our composite induction bottom options include Brazed Base which is a cost-effective solution and Impact-Bonded Base which ensures a strong, seamless bond between layers for enhanced durability.

For heat core materials we also have two options: Aluminum Core and Copper Core, offering superior heat conductivity for precise temperature control.

Material Choices for Durability and Cost Control

To support your budget and quality requirements, Bonray offers:

- 304 Stainless Steel – Excellent corrosion resistance, ideal for premium cookware lines.

- 201 Stainless Steel – A more economical alternative with solid durability for budget-conscious markets.

Material thickness can be adjusted based on your performance goals and cost considerations.

Lid Customization for Enhanced Cooking Control

Bonray offers a variety of lid options to improve cooking efficiency and meet user preferences:

- Stainless Steel Lids: Durable and ideal for professional kitchens where breakage resistance is essential.

- Tempered Glass Lids: Allow users to monitor cooking progress without lifting the lid, reducing heat loss and improving energy efficiency.

- Vented Lids: Designed to control steam release and prevent boil-overs in commercial kitchens.

Each lid can be customized with logo engraving, custom handle designs, or specialized rim finishes.

Handle Design for Safety and Comfort

Our cookware products feature multiple handle options designed for improved strength, safety, and comfort:

- Riveted Handles: Provide maximum stability and long-term durability.

- Welded Handles: Offer a smooth, seamless design for added strength and easy cleaning.

- Ergonomic Handles: Shaped for improved grip and user comfort, reducing hand fatigue.

- Heat-Resistant Handles: Stay cool during cooking to enhance safety in busy kitchens.

Custom Packaging Solutions for Retail and Wholesale

Our flexible packaging solutions are designed to support various sales channels:

- Retail-Ready Boxes: Ideal for supermarket shelves and retail displays.

- Branded Gift Sets: Designed for promotional campaigns and seasonal product lines.

- Bulk Protective Packaging: Provides enhanced protection for large orders during shipping and storage.

Custom packaging can be tailored with logo printing, product descriptions, and care instructions to improve your product’s retail appeal.

Estimated Cost Analysis For Stainless Steel Cookware

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a 40 ft container of griddles :

Some countries require imported products to undergo inspection and testing to ensure that they meet certain safety and quality standards.

$5,000

Shipping costs can vary depending on the size and weight of the shipment, as well as the shipping method used. Take the US as an example, the sea freight for a 40'HQ costs about $4000.

$4,300

When importing goods from China, you may be subject to customs duties and taxes. The amount of duties and taxes vary depending on the country of import and the value of the shipment. It's important to research the duties and taxes applicable to your specific country of import to ensure that you are aware of the additional costs involved.

10% of the invoice amountEfficientCookwareProduction Schedule

At Bonray, we understand that timely delivery is crucial for your business. Our efficient cookware production schedule is designed to ensure your orders are manufactured, inspected, and shipped on time — without compromising quality.

With streamlined processes, advanced machinery, and experienced technicians, we optimize every stage of production to meet your deadlines. Whether you’re placing a trial order or managing large-scale production, we prioritize efficiency to help you maintain inventory flow and meet customer demand.

Trust Bonray to deliver reliable stainless steel cookware — on time, every time.

Step 1: Material Preparation (3-7 days)

Material Cutting: Raw stainless steel sheets are cut to the required size using cutting machines to ensure precision of the stainless steel cookware.

Step 2: Cookware Body Process (8-10 days)

- Rolling: The cut material is rolled into a cylindrical cookware shape.

- Seam Welding: The vertical seam is securely welded for durability.

- Seam Flattening: The welded seam is pressed to ensure a smooth, even surface.

- Seam Grinding: The seam is carefully polished for a seamless finish.

- Body Shaping: The cylinder is adjusted to ensure perfect roundness.

- Edge Trimming: The top edge is shaped and flanged for added strength and aesthetics.

Step 3: Cookware Base Process (10-15 day)

- Deep Drawing: Stainless steel is drawn into the desired base shape.

- Aluminum Core Bonding: Using friction welding, an aluminum core or copper disc is bonded between stainless steel layers to create a 3-ply or 5-ply clad bottom for superior heat distribution.

- Edge Cutting and Shaping: The base is trimmed and shaped for a clean finish.

- Base Polishing: The inner and outer base surfaces are polished for a smooth, professional look.

Step 4: Assembly Process (10-12 days)

- Seam Welding: The cookware pot or pan body and base are welded together using a durable circular seam weld.

- Seam Pressing: The welded seam is pressed for reinforcement, ensuring no leaks (tested with a water-tightness check).

- Seam Polishing: Both the inner and outer seams are carefully polished to ensure a smooth surface.

- Sanding Finish: The entire cookware pot or pan is sanded to achieve a uniform texture.

Step 5: Cookware Handle Process (5 days)

- Handle Plate Stamping: Handle plates are stamped from stainless steel sheets.

- Wire Stamping: Stainless steel wire is stamped and shaped to form durable handles.

- Handle Welding: The handle plate and wire are securely welded together.

- Handle Installation: The completed handles are riveted onto the cookware pot or pan body for firm attachment.

Step 6: Cookware Lid Process (4 days)

- Deep Drawing: Stainless steel sheets are drawn into the desired lid shape.

- Edge Trimming: The lid edges are cut and shaped for a clean finish.

- Cleaning: Lids are thoroughly cleaned to remove dust and debris.

- Sanding Finish: The interior and exterior of the lid are polished for a smooth surface.

- Lid Handle Welding: The lid handle is securely welded in place.

Step 7: Final Assembly Process and Packaging (3-5 days)

- Inspection: Each finished cookware product undergoes a detailed quality check to ensure no defects.

- Cleaning: Products are cleaned to maintain a flawless finish.

- Packaging: Cookware products are carefully packed to prevent damage during transport.

Rigorous Quality Assurance — Ensuring Reliability in Every Cookware

Every Bonray stainless steel cookware undergoes strict quality checks to meet international standards. From material selection to final inspection, we ensure your cookware products are durable, safe, and built to perform — giving you confidence with every order.

Industry insights

Expert Guidance for Sourcing Cast Iron & Stainless Steel Griddles

Bulk-order buyers often face complex challenges when sourcing griddles and grill pans, particularly when balancing quality, cost efficiency, and brand differentiation. Below, we provide expert insights to help importers, wholesalers, supermarket buyers, brand owners, and distributors make more informed decisions about material selection, manufacturing processes, and supplier partnerships. This knowledge ensures you address common pain points and maximize value across your supply chain.

1. Material Selection: Cast Iron vs. Stainless Steel

Cast Iron Griddles

- Advantages: Exceptional heat retention, naturally nonstick surface once seasoned, and enhanced flavor development.

- Pain Points: Heavier weight increases shipping costs; requires seasoning and careful maintenance to prevent rust.

Stainless Steel Griddles

Advantages: Corrosion resistance, easier cleaning, and consistent cooking performance without the need for seasoning.

Pain Points: Less heat retention compared to cast iron; often higher initial material cost for premium grades (e.g., 304 stainless).

2. Manufacturing Processes & Quality Control

Cast Iron Production: Typically formed using sand-mold casting, followed by precision grinding or polishing. Confirm your supplier’s foundry capabilities and examine sample weights, thickness consistency, and smoothness.

Stainless Steel Production: Often involves stamping or forging techniques, tri-ply layering for improved heat conduction, and finishing treatments (e.g., brushed or polished surfaces). Look for quality inspections at each stage—particularly weld points for handles and rim edges.

3. Key Considerations for Bulk Buyers

Consistent Quality: Request batch test reports, material certifications, and sample evaluations to ensure uniformity in thickness, finish, and performance.

Lead Times & Logistics: Cast iron products can require more extensive finishing, while stainless steel fabrication might need advanced tooling. Factor in these production schedules when setting delivery timelines.

Cost Management: Volume-based pricing can be negotiated, but confirm suppliers maintain consistent raw material sources to avoid sudden cost spikes.

4. Customization & Branding

Handle Options: Choose between wood, silicone, or stainless steel handles for aesthetic, heat-resistance, and brand alignment.

Logo Application: Request laser engraving, embossing, or stamping to differentiate your line and support brand recall.

Packaging Solutions: Investing in quality packaging reduces product damage during transit and elevates in-store presentation.

5. Ensuring Compliance & Safety

Food-Grade Certifications: Verify suppliers hold relevant certifications (e.g., FDA, LFGB) to meet international food-contact standards.

Durability & Warranty: A robust warranty demonstrates manufacturer confidence and protects your investment in case of defects.

Client Success Story: Custom Stainless Steel Saucepan Grill Pan for a European Kitchen Tools Brand

Client Background

Our client, a European kitchenware distributor, specializes in premium cookware solutions designed for both home enthusiasts and professional chefs. They sought a reliable manufacturer–Bonray to produce a custom stainless steel grill pan that would stand out in terms of performance, durability, and high-end aesthetics.

Customization Project Brief:

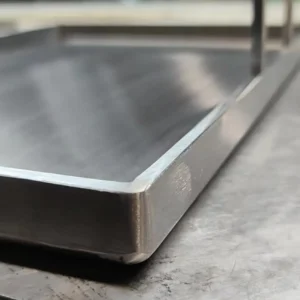

The distributor provided detailed technical drawings outlining a rectangular grill pan with the following specifications:

Material: 430 stainless steel

Thickness: 3.0 mm

Structure: Four welded corners, with dual handles securely welded on both sides

Surface Finish: Brushed surface on both the cooking area and sidewalls

They also requested a premium look and feel suitable for the European market, emphasizing consistent quality and an appealing design.

Custom Engineering Process

1. Corner Design Options

We proposed two corner approaches—rounded corners versus sharp edges. And create two corner effects for customer to choose.

Here is the rounded corner vs sharp edges of the custom grill pan.

Here is the sharp corner for the grill pan.

After reviewing sample visuals, the client chose rounded corners for both practical and aesthetic reasons: they reduce stress points and create a sleek, modern appearance.

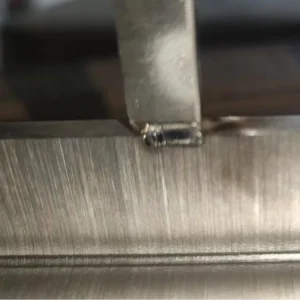

2. Precision Welding & Thorough Weld Cleaning

Laser Welding: We utilized laser welding to join the 3.0 mm stainless steel panels. This method minimizes heat distortion and allows for strong, clean seams.

Weld Seam Cleaning: After welding, our team meticulously cleaned each weld seam to remove discoloration or residue. This ensures not only a polished look but also maintains the integrity and hygiene of the cookware.

3. Handle Attachment

The distributor specified dual side handles for safer lifting and transporting of the grill pan. We applied argon arc welding technique to weld the handles firmly onto the pan’s sidewalls, reinforcing each junction for long-term durability and a secure grip under high-heat, heavy-load conditions.

Sample Testing & Design Refinement

Initial Flat-Bottom Samples

The first prototypes followed the exact dimensions and were tested in high-heat scenarios. While the welding and overall construction met expectations, the flat-bottom design led to slight warping when exposed to extreme temperatures.Curved-Base Solution

To solve the warping issue, our engineering team introduced a gentle concave curve on the pan’s base. This design accommodates the metal’s natural expansion under heat, ensuring it remains stable and level during cooking. The revised samples passed all subsequent tests without any deformation.

Manufacturing Advantages

Technical Expertise: Our experience in stainless steel fabrication, laser welding and fine polishing techniques enabled us to deliver a robust grill pan with minimal heat distortion and a clean, polished aesthetic.

Attention to Detail: From the rounded corners to thorough weld seam cleaning, every component reflects our commitment to quality and finishing excellence.

Collaborative Problem-Solving: We worked closely with the client, iterating on the design after testing revealed potential issues. Our prompt solution to introduce a curved base prevented warping and maintained overall performance.

Reliable Production Capacity: As a cookware manufacturer, we accommodate both custom orders and large-scale production runs, aligning with each client’s specific volume and branding requirements.

Outcome

The final custom stainless steel grill pan embodied the distributor’s original vision for a premium, durable product suitable for the European market. The combination of 430 stainless steel, thick-gauge construction, precise laser welding, and a concave base design delivered exceptional heat performance and longevity. The collaborative process—spanning concept evaluation, sample testing, and final production—showcased our capability to address unique specifications while ensuring consistent quality.

This project underscores our commitment to delivering custom cookware solutions that stand up to real-world demands. By prioritizing technical innovation, rigorous quality control, and efficient communication, we help our B2B partners elevate their product lines and strengthen their brand reputation.

Bonray is a reliable stainless steel cookware manufacturer with proven expertise in cookware production. Businesses worldwide trust us because we offer:

With over 15 years of manufacturing experience, Bonray has delivered 100+ customized stainless steel cookware solutions to bulk buyers worldwide. Our 98% on-time delivery rate, flexible MOQs, and market-driven designs ensure you get cookware solutions that meet your business needs. Supported by our 24/7 professional team, we’re committed to providing the best stainless steel cookware with reliability you can trust.

- Over 100 Custom Cookware Solutions

- 15+ Years of Manufacturing Expertise

- 98% On-Time Delivery Rate

- Flexible MOQ for Bulk Buyers

- 24/7 Professional Support

The FAQs About Griddles & Grill Pan

When sourcing griddles & grill pans for retail or commercial use, bulk buyers often have concerns about materials, performance, and customization. Below are answers to common questions that may help you make informed decisions.

A griddle typically has a flat surface suited for pancakes and stir-frying, while a grill pan features raised ridges that create sear marks and allow grease drainage.

Cast iron delivers excellent heat retention but is heavier to ship, whereas stainless steel resists corrosion, offers easier cleaning, and can reduce overall maintenance costs.

Yes. If made with induction-compatible stainless steel (e.g., 430 stainless) or cast iron, the grill pan will work on induction stoves.

Tri-ply cookware integrates steel and aluminum layers, enhancing heat distribution and reducing hot spots to achieve consistent cooking results.

Partner with a cookware factory that offers robust quality control measures, regular batch inspections, and relevant certifications like ISO or LFGB.

Lead times vary by order volume and design complexity, but most kitchenware manufacturers estimate 30 to 60 days from confirmed drawings to final shipment.

Yes. Bonray cookware offer OEM/ODM services, letting you add logos, custom finishes, and packaging for brand consistency.

Request freight quotes from the manufacturer or a freight forwarder. Many suppliers handle FOB (Free on Board) terms, and you can coordinate ocean or air transport as needed.

Yes. Most stainless steel pans are dishwasher-safe, although handwashing can help preserve the brushed finish.

MOQs can range from 300 to 1,000 units depending on the factory’s policies, design complexity, and material requirements.

Selecting heavier-gauge steel (e.g., 3.0 mm or thicker) and incorporating a slight curved base design helps minimize warping under high heat.

Laser welding ensures seamless joints with minimal heat distortion, creating stronger corners and a smoother look for professional cookware lines.

Yes. 430 stainless steel is food-safe, induction-compatible, and widely used for commercial cookware due to its corrosion resistance and affordability.

Yes. As a cookware factory, Bonray provides prototype samples or small test runs to confirm dimensions, finishes, and performance prior to mass production.

Allow the griddle to cool, then rinse with warm water and mild detergent. Use a non-abrasive scrubber to protect the brushed surface.

Manufacturers typically offer brown box, color box, mail-order box, or custom packaging. Ask about branding and protective materials to avoid transit damage.

Share detailed drawings, material specs, and order quantities with the supplier. They will evaluate production feasibility, recommend modifications if needed, and provide a formal cost estimate.

Consider consolidating shipments under one freight forwarder, negotiating volume-based rates, or choosing sea freight for cost-effectiveness on larger loads.

Depending on established relationships, some cookware factories offer partial deposits, extended payment schedules, or letters of credit to accommodate bulk purchasers.

If modifications arise after production begins, Bonray will update cost estimates and delivery timelines. We'll provide revised samples if changes significantly alter product specifications.

Yes. Clients frequently request brushed, polished, or nonstick coatings. Discuss feasibility and performance requirements with your cookware supplier to confirm suitability.

Options range from branded boxes and mail-order packaging to eco-friendly materials. Many factories can also meet retailer-specific requirements (e.g., barcodes, inserts).

As an experienced cookware factory, Bonray forecasts raw material needs, schedules production shifts, and increases staff to meet higher volumes while maintaining quality.

Yes. Providing the same specs and order reference ensures consistent replication. Factories typically keep molds, drawings, and settings on file for reorders.

Many bulk buyers use just-in-time inventory or contract warehousing. Plan storage space and handling procedures for large shipments to maintain product quality and streamline distribution.

Reputable suppliers offer replacement policies or credit adjustments. They may request photos or samples of damaged goods to improve quality control.

Yes. As a cookware supplier, Bonray accommodates independent testing for safety, material composition, or performance to meet your specific compliance standards.

The Basic Knowledge About Stainless Steel Cookware

Ready to Partner with Bonray?

Tell us your requirements, and our team will provide a tailored solution that fits your business goals.

Complete Your Professional Cookware Collection

Comprehensive set including sauce pans, stock pots, and frying pans for commercial kitchens

Available in 6-20 quart capacities for large-batch cooking in professional settings

Straight-sided pans for sautéing, simmering, and deglazing, optimized for consistent heat and controlled cooking.

Wide and deep cookware with dual handles, suitable for stews, braising, and slow cooking in volume meal prep environments.