Stockpot Manufacturing Process Unveiled: From Raw Steel to Flawless Finish

Stainless steel cookware manufacturing represents one of the most sophisticated metalworking processes in the modern kitchen equipment industry. As global demand for durable, high-quality cookware continues to rise, understanding the cookware manufacturing process becomes crucial for importers, distributors, and retailers. Sourcing cookware is not merely a transaction. It’s about ensuring quality, consistency, and a reliable partnership. This article explains the entire stainless steel stockpot production process, allowing you to make informed decisions and work with the best OEM cookware manufacturer in China for custom cookware development and large-scale production orders.

Why Understanding the Stockpot Manufacturing Process is Necessary

Before we dive into the machinery and technical steps, let’s address a crucial question: why does this matter to your business?

- Quality Assurance: Knowing the process allows you to ask the right questions about quality control. You can identify potential failure points (like welds or seams) and verify that your manufacturing partner has a robust process to ensure strength and longevity.

- Informed Sourcing & Cost Evaluation: Understanding the labor, machinery, and material inputs at each stage helps you better evaluate quotes. You can distinguish between a low price that cuts corners and a fair price that guarantees quality.

- OEM Customization Potential: This guide showcases our standard process. For brand owners, each step is an opportunity for customization. Do you need a thicker gauge of steel for heavy-duty use? A specific type of handle? A brushed or polished finish? A different base for induction compatibility? Knowing the process empowers you to collaborate effectively on product development.

- Building a Resilient Supply Chain: Partnering with a manufacturer who is open about their process is partnering with an expert who is confident in their capabilities. This transparency is the foundation of a reliable, long-term relationship.

How to Identify a High Quality Stainless Steel Stockpot

It’s also crucial to understand the essential elements that make a superior stockpot. Performance, durability, and safety are all determined by the choices made here.

Material Matters: 304 vs. 316 Stainless Steel

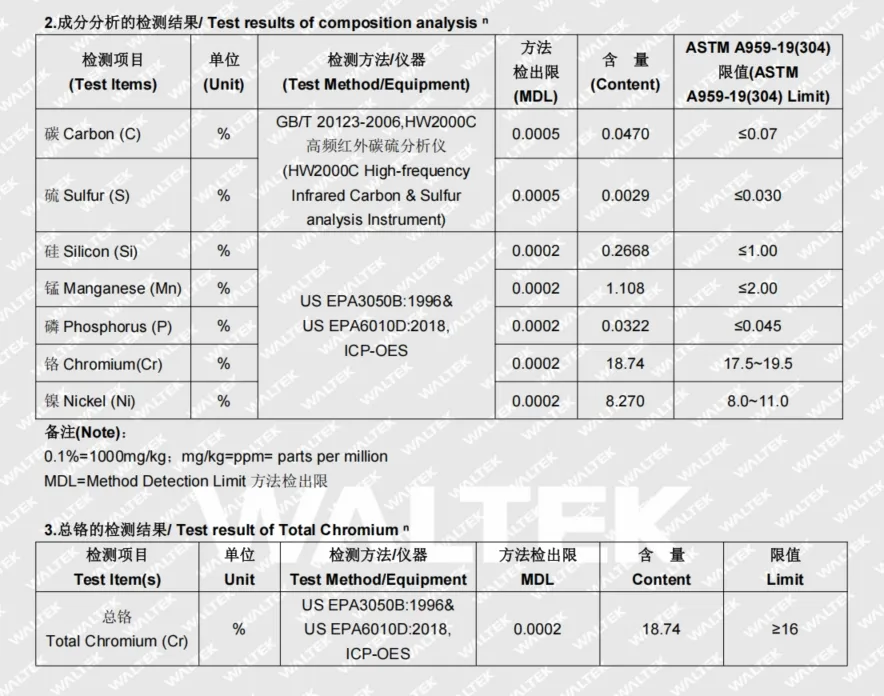

The foundation of exceptional stainless steel cookware begins with material selection, typically utilizing food-grade 201 or 304 or 316 stainless steel, the latter two types containing 18% chromium and 8-10% nickel for optimal corrosion resistance and durability.

| Feature | 304 Stainless Steel (18/8) | 316 Stainless Steel (18/10) |

|---|---|---|

| Composition | ~18% Chromium, ~8% Nickel | ~18% Chromium, ~10% Nickel, +2% Molybdenum |

| Corrosion Resistance | Excellent for general use. The industry standard. | Superior, especially against chlorides and salts. Ideal for marine environments or frequent brine use. |

| Cost | More economical. | Higher due to molybdenum content. |

| Best For | Vast majority of commercial and home kitchens. | High-end cookware lines, medical applications, or specialized culinary environments. |

Professional manufacturers implement rigorous material testing protocols, including chemical composition analysis and physical property verification, to ensure consistent quality throughout production.

High-quality stainless steel sheets undergo comprehensive inspection for uniformity, surface finish, and structural integrity before entering the production line . This initial quality control step prevents defects that could compromise the final product’s performance and longevity .

The Engine of a Stockpot: Tri-Ply Composite Base

A single layer of steel heats up unevenly, resulting in hot spots that scorch food. The solution is a multi-layer composite base, often known as a tri-ply base. This technology is an important characteristic of high quality cookware.

Structure: It consists of a highly conductive aluminum or copper core, pressure-bonded or high-frequency brazed between an inner layer of food-grade 201/304/316 stainless steel and an outer layer of magnetic 430 stainless steel (for induction compatibility).

Key Benefits: This “sandwich” construction ensures rapid, even heat distribution, eliminates hot spots, improves energy efficiency, and reduces warping.

Advanced Manufacturing Equipment and Technology

Modern stainless steel pot production requires advanced equipment including high-precision cutting machines, hydraulic presses capable of exerting 150+ tons of pressure, and advanced welding systems . Professional manufacturers invest in state-of-the-art laser cutting technology and CNC machinery to achieve consistent dimensional accuracy and superior surface finish .

The 7-Stage Stainless Steel Stockpot Manufacturing Process

Let us now walk through the production floor. Here’s the effective seven-stage process that takes a Bonray stockpot from raw steel sheet to completed culinary workhorse. This process is optimized for the large-capacity, heavy-duty stockpots required in commercial kitchens.

Stage 1: Initial Raw Material Preparation and Precision Cutting of Stockpot

1.1 Precision Material Cutting Process

The manufacturing process begins with precision cutting to prepare stainless steel sheets (typically high-grade SUS304 or as specified by the client) to exact specifications. We use a high-precision shearing machine for this.

This isn’t just about size. Precision cutting ensures that when the sheet is rolled, the edges will meet perfectly for welding. Any error here would compromise the structural integrity of the entire bucket, leading to a weak seam or an imperfectly cylindrical shape. At Bonray, we use laser cutting to achieve clean, precise edges that minimize material waste and ensure consistent component dimensions.

1.2 Quality Control at the Cutting Stage

Before forming process begins, each cut component is inspected to ensure the dimensions and edges meet the quality requirements. This early stage quality control prevents costly rework and ensures consistency throughout the whole production process.

Stage 2: Stockpot Lid Manufacturing Process

A stockpot is incomplete without a perfect lid. A well-made lid is essential for hygiene, heat retention, and spill prevention. The production process is as precise as the main body’s.

2.1 Stockpot Lid Forming and Shaping

Lid manufacturing uses deep drawing techniques similar to bottom component production, but with different dimensional requirements. The forming process creates the domed shape while maintaining consistent wall thickness .

Professional cookware manufacturer like Bonray utilize specialized tooling developed for lid geometry to ensure proper fit and function. The forming process requires careful control of material flow to prevent wrinkling or tearing.

2.2 Stockpot Lid Edge Trimming and Finishing

The stockpot lid components are precisely trimmed to provide perfect dimensional tolerances and a smooth edge finish. In the trimming process, Bonray uses CNC machinery to provide consistent edge geometry and surface finish. This technique provides a proper fit with the pot body and produces an appealing appearance.

2.3 Stockpot Lid Handle Installation and Final Assembly

In the installation process, we use spot welding technique to weld the handle securely on the center of the stockpot lid. Bonray use specialized fixtures designed specifically for lid handle installation to ensure accurate positioning and installation welding quality.

Stage 3: Stock Pot Body Formation and Welding

In this process, we roll the flat sheet to a cylinder. It involves a series of critical steps that define the bucket’s core structure and seam strength.

3.1 Cylindrical Body Formation

The pot body formation process involves rolling flat stainless steel sheets into cylindrical shapes using specialized forming equipment. This operation requires precise control of rolling pressure and alignment to achieve consistent wall thickness and perfect cylindrical geometry.

Professional manufacturers like Bonray Cookware utilize hydraulic forming presses with programmable controls to ensure repeatable results across large production runs. The forming process must account for material spring-back and work hardening characteristics to achieve final dimensional accuracy.

3.2 Straight Seam Welding Technology

Once rolled, the two edges of the steel sheet meet to form a seam. We use advanced automated welding techniques like TIG (Tungsten Inert Gas) welding or Laser welding to fuse the edges and create strong joints.

The longitudinal seam welding process employs TIG (Tungsten Inert Gas) welding or laser welding techniques, resulting in strong, consistent joints. Regarding stockpot body seams with thin material thickness, we usually use laser welding, which provides superior control over heat input and penetration depth, resulting in high-quality welds with minimal distortion .

- The Bonray Difference: This is a critical quality checkpoint. A poor weld can result in different level of leakage or corrosion. Our automated welding system with real-time monitoring ensures consistent weld quality and minimize human error. This results in a seamless, hygienic interior and superior structural strength. The welding process requires careful control of travel speed, arc voltage, and shielding gas composition to achieve optimal results .

3.3 Seam Finishing and Grinding

Following welding, as the newly welded straight seam is slightly raised, it will undergo precision grinding to achieve smooth surface finish and dimensional accuracy. This process removes any weld reinforcement and creates a seamless appearance that meets professional cookware standards .

To complete the grinding operation, our skilled technicians use specialized pressing equipment to grind the seam both inside and out, so as to maintain smooth consistent surface finish.

- Why Bulk Buyers Should Care: This two-step procedure is essential for hygiene and appearance. A flawlessly ground seam removes any spaces where germs may grow, which is a must for commercial kitchen and food-grade applications. Additionally, it produces a perfect, high-end finish that consumers value.

3.4. Barrel Rounding & Shaping

Even after rolling, slight irregularities in circularity may occur. The pot is placed on a rounding machine to polish its cylindrical shape. Following that, the interior of the weld line is lathed to gain perfect smoothness.

3.5. Top Edge Flanging

Finally, the top edge of the barrel is rolled outwards to create a smooth, reinforced rim, also known as a flange.

Stage 4: Stockpot Bottom Component Manufacturing

The bottom of the stockpot does more than just keep things in place; it determines the product’s stability and, in the case of cookware, heating capability.

4.1 Deep Drawing/Stamping and Forming

Bottom component production utilizes deep drawing techniques to form complex shapes from flat stainless steel blanks . This process requires multiple drawing stages with intermediate annealing to prevent cracking and ensure dimensional accuracy .

Professional manufacturers employ progressive die systems that gradually form the bottom component through a series of controlled deformation steps . Each drawing stage must be carefully controlled to prevent tearing or excessive thinning of the material .

4.2 Tri-Ply Composite Bottom via High-Frequency Brazing

Advanced cookware designs incorporate tri-layer bottom construction featuring aluminum core bonded between stainless steel layers for enhanced heat distribution . This construction requires specialized high-frequency brazing equipment and precise temperature control during the bonding process .

The aluminum core provides superior thermal conductivity while the stainless steel layers maintain durability and corrosion resistance . This tri-layer construction significantly improves cooking performance and energy efficiency .

4.3 Edge Trimming and Machining

The formed bottom components undergo precision trimming and machining operations to achieve exact dimensional tolerances . CNC machining centers ensure consistent edge geometry and surface finish across all components .

This precision machining stage is critical for achieving proper fit-up during assembly operations and ensuring leak-proof joints in the finished product . Advanced manufacturers maintain tight dimensional tolerances to minimize assembly variations .

4.4. Bottom Grinding & Polishing

The base is meticulously ground and polished to remove any marks from the manufacturing process, ensuring a smooth, flawless surface.

Stage 5: Stockpot Assembly and Circumferential Welding

This process combines the formed bucket body and encapsulated base, creating a single, strong vessel. The technique of connection is critical, as it directly influences the stockpot’s ability to hold its contents without leakage and withstand the stresses of daily use.

5.1. Circular Seam Welding

The finished pot body is placed upside down, and the finished base is fitted perfectly onto it. An automated circular welding machine then performs a 360-degree weld, fusing the side wall of the barrel to the edge of the base. This critical welding process requires precise control of heat input and welding parameters to prevent distortion and ensure complete penetration.

5.2. Weld Seam Pressing & Water-Leak Testing

The circular weld is pressed to flatten and strengthen it. Then comes the most important quality control step: every single bucket is filled with water and inspected for leaks. This is not a spot check; it’s a 100% guarantee. Any unit with even the slightest sign of a leak is immediately rejected.

5.3. Circular Weld Grinding & Polishing

Once a bucket passes the water test, the circular weld seam is carefully ground and polished, both inside and out. This ensures a smooth transition between the base and the walls, which is essential for hygiene and aesthetics.

5.4. Full Body Sanding/Polishing

The entire bucket, which is now fully constructed, undergoes its final surface treatment. Depending on the client’s OEM specifications, a satin sanding finish or a mirror finish polishing could be applied to both the interior and exterior.

5.5 Rim Reinforment

The top rim of the stockpot is also a high customized area. Bonray offer two options of stockpot rim, one is flared rim and the other is straight rim.

Stage 6: Stockpot Handle Manufacturing and Installation

The value of a stockpot depends on its handles. This stage combines metal stamping and precision assembly to create strong, ergonomic handles.

6.1. Stamping the Handle Plates

We cut and form the stainless steel sheets into flat plates through a stamping press, which will then attach the handle with steel plate to the stockpot body.

6.2. Forming the Wire Bail

We then bend and mold the stainless steel wire into the traditional “bail” or handle grip.

6.3. Welding the Handle Assembly

And we use automatic robotic welding arms to weld the wire bail on the stamped handle plates, creating a single, robust handle.

Handle assembly requires precise welding of steel wire components to base plates under controlled welding conditions. Professional cookware manufacturer like Bonray utilizes robotic laser welding arm and welding fixture to ensure the handle’s welding quality and structural integrity.

6.4 Riveting and Final Installation

After precise hole punching on the handle plate, our skilled technicians use high-pressure riveting technique to assemble the handle on the stockpot body, creating strong and secure attachments to the pot body.

- Why Rivets? While welding is an option, riveting provides immense shear strength. For stockpots designed to carry heavy loads (liquids, food ingredients, etc.), rivets offer a secure and durable attachment that can withstand years of stress. We can, of course, accommodate requests for welded handles as part of our OEM service.

Stage 7: Final Inspection and Quality Control

The manufacturing is complete, but the process is not. This final stage is our last promise of quality to you. It is a comprehensive and systematic check to assess that every single stockpot meets the client’s exact specifications as well as our own strict internal standards.

7.1. Final Quality Inspection

Each finished bucket and lid is subjected to a final, comprehensive visual and tactile inspection. Our QC team checks for:

- Surface imperfections (scratches, dents, discoloration).

- Weld integrity and finish.

- Handle security and alignment.

- Dimensional accuracy.

- Lid fit and finish.

7.2. Final Cleaning

This process utilizes specialized cleaning solutions and equipment designed specifically for stainless steel cookware. To make sure the product is perfect and ready to use straight out of the box, final cleaning process remove all oils, fingerprints, and manufacturing residues.

7.3. Custom Packaging

This is where your brand comes to life. Final packaging utilizes protective materials and methods designed to prevent damage during shipping and storage.

As an OEM cookware partner, we package the products according to your requirements. This can include individual poly bags, custom-printed boxes, master cartons for bulk shipping, barcode labeling, and the inclusion of any instructional materials.

Conclusion: Choosing the Right Kitchenware Manufacturing Partner

Understanding our manufacturing process is critical, but selecting the proper partner requires more than simply production capability. Bonray provides a broad partnership including consistency at scale, uncompromising quality, and the deep manufacturing expertise required for true OEM partnership, aiming to help you achieve your business’s objectives.

- Strong Customization Capabilities (OEM/ODM): As a true OEM stainless steel kitchenware supplier, we are not just assembling products; we are co-creating them with you. Our in-house R&D and engineering teams thrive on challenges.

Our OEM services include:

- Custom pot shapes, sizes, and capacities.

- Choice of materials (304 vs. 316 steel) and thickness.

- Unique handle and lid designs.

- Custom logo application via laser engraving or stamping.

- Custom packaging and branding.

- A Culture of Quality Assurance: For Bonray, quality is not a department; it’s our culture. We understand that for wholesale partners, consistent quality is the basis of trust and profitability. We actively help clients select the right materials and design features to ensure products are not only well-made but also perfectly suited for their end market. Our commitment to standards like ISO, BSCI, FDA, and LFGB is a testament to our dedication to global best practices.

- Direct-from-Manufacturer Supply Chain & Cost Efficiency: By partnering directly with Bonray, you avoid the markups and communication delays that come with trading companies and intermediaries. This direct line provide better cost transparency, more responsive service, and a more reliable and predictable supply chain. Our expertise in metal fabrication and lean manufacturing methods ensures we operate efficiently, passing on the cost savings to you and enhancing the competitiveness of your products in the market.

Frequently Asked Questions (FAQ)

We believe in proactive communication. Here are answers to some of the most common questions we receive from our overseas kitchenware partners.

- What is your Minimum Order Quantity (MOQ)?

Our MOQ is determined on a case-by-case basis, depending on the product’s size, complexity, and tooling requirements. For standard items, we can be quite flexible. For fully custom projects, the MOQ will factor in any necessary mold or die development. Please contact us with your detailed specifications; our sales team will work with you to find a viable and mutually beneficial solution.

- What is the lead time from placing an order to shipment?

Lead times vary based on the specifics of the order. As a general guideline, standard production runs typically take 4-6 weeks after the order is confirmed and the deposit is received. For custom orders requiring new tooling, the initial lead time may be 6-8 weeks, which includes mold fabrication and sample approval. We are committed to transparency and will provide a firm and reliable delivery schedule in your formal contract.

- Can you manufacture products using 316 stainless steel?

Yes, absolutely. While 304 stainless steel is the industry standard for most food-grade applications, we are fully equipped and experienced in working with 316 stainless steel. This grade offers superior corrosion resistance, especially against chlorides and industrial chemicals, and is an excellent choice for marine, pharmaceutical, or other highly demanding environments.

- How do you ensure product food safety and compliance with standards like FDA and LFGB?

We build compliance into our process from the very start. We source certified food-grade raw materials and maintain strict hygiene protocols throughout production. We can provide all necessary documentation and work with accredited third-party labs like SGS or TUV to conduct specific tests and provide official certification for FDA, LFGB, or other international standards as required for your market.

- Can I customize the product size, shape, or add my Logo?

Yes, customization is our specialty. As a dedicated OEM/ODM kitchenware manufacturer, we can accommodate a wide range of modifications. This includes adjusting dimensions, creating entirely new shapes, selecting specific surface finishes (mirror, brushed, etc.), choosing from various handle and lid styles, and permanently applying your logo via methods like laser engraving, stamping, or etching. Simply provide your design drawings or detailed requirements, and our engineering team will collaborate with you to make it a reality.