304 vs. 201 Stainless Steel: A Crucial Decision for Your Cookware Brand’s Success

Choosing the right stainless steel for your new cookware line is more than a technical detail; it’s a strategic business decision that directly impacts your brand’s reputation, profit margins, and long-term customer loyalty. As a global buyer or brand manager, you’ve likely encountered two primary options from suppliers: 304 and 201 stainless steel, which are the most common material in cookware manufacturing.

Outwardly, they look nearly identical. But beneath that polished surface lies a world of difference in performance, durability, and cost. Making the wrong choice can lead to customer complaints about rust, tarnishing your brand’s image, or it can mean overspending on materials, eroding your competitive edge in a price-sensitive market.

This guide, written from a manufacturer’s perspective, provides an in-depth analysis and a clear, unbiased comparison of 304/18-10 vs. 201 stainless steel to help you make the most intelligent cookware material selection for your specific market and brand positioning. Our goal at Bonray is to empower you with the knowledge to make informed procurement decisions.

304 or 201 Stainless Steel, How to Choose for Your Cookware Business

What’s the Real Difference? A Look Inside 304 and 201 Stainless Steel

The performance of stainless steel is primarily determined by its chemical composition, especially its chromium (Cr) and nickel (Ni) content. To understand the difference, we need to talk about one key ingredient: Nickel.

While both 304 and 201 are types of austenitic stainless steel containing chromium (which provides the basic rust resistance), the percentage of nickel is the game-changer.

- 304 Stainless Steel (also known as 18/8 or 18/10): This is the industry gold standard for high-quality kitchenware. The “18/8” designation means it contains approximately 18% chromium and 8-10% nickel. This high nickel content gives it superior resistance to corrosion and rust, even when exposed to acidic foods (like tomato sauce) and harsh detergents. It is universally recognized as the premier food-grade stainless steel.

- 201 Stainless Steel: This grade was developed as a lower-cost alternative to 304. To reduce costs, manufacturers substitute most of the expensive nickel with more affordable elements like manganese (Mn) and nitrogen (N). While it still offers good hardness and a polished finish, its reduced nickel content, typically between 3.5% and 5.5%, makes it more susceptible to corrosion over time, especially in saline or acidic environments.

Head-to-Head Comparison: 304 vs. 201 for Commercial Cookware

For a quick overview, here’s how the two materials stack up in the areas that matter most to your business:

| Feature | 304 Stainless Steel (18/8) | 201 Stainless Steel | Why It Matters for Your Business |

|---|---|---|---|

| Corrosion Resistance | Excellent. Highly resistant to rust, pitting, and corrosion from acids and salts. | Good. Sufficient for many applications, but vulnerable to long-term exposure to acidic foods and salt, potentially leading to rust spots. | Brand Reputation & Lower Return Rates. 304 ensures product longevity and customer satisfaction. |

| Durability & Formability | Excellent. More ductile and easier to deep-draw into complex shapes like stockpots without cracking. | Good. Harder and slightly more brittle, which can pose challenges in complex manufacturing processes. | Design Freedom & Production Yield. 304 allows for more intricate designs and a higher success rate in production. |

| Food Safety | The Gold Standard. Globally recognized as safe and non-reactive for all types of food contact. | Generally Safe. Considered safe for most food contact, but 304 is the superior choice for guaranteed non-reactivity with acidic ingredients. | Compliance & Consumer Trust. Using 304 aligns with the highest international food safety standards. |

| Cost | Higher. Nickel is a costly commodity, making 304 a premium material. | Significantly Lower. The primary advantage of 201 is its cost-effectiveness, allowing for more competitive pricing. | Profit Margins & Market Positioning. 201 enables entry into price-sensitive markets or budget-friendly product lines. |

| Appearance | Polished, bright finish that is highly durable. | Initially indistinguishable from 304, but may lose its luster or develop stains more easily over time. | Long-Term Brand Image. 304 maintains its premium look for longer, reflecting well on your brand’s quality. |

The Strategic Choice: Which Stainless Steel is Right for YOUR Brand?

The decision isn’t about which material is “better” in a vacuum, but which is the “right fit” for your brand’s promise and target audience.

Choose 304 Stainless Steel IF…

- Your brand is positioned as premium, professional, or mid-to-high end.

- Your target customers value longevity, performance, and “buy-it-for-life” quality.

- Your product marketing emphasizes superior quality and durability.

- The cookware, such as a stainless steel stockpot, will be marketed for all-purpose use, including slow-cooking acidic sauces or brining.

- You want the absolute best stainless steel for pots to build unwavering brand trust and minimize after-sales issues.

Consider 201 Stainless Steel IF…

- You are targeting a highly price-sensitive market segment or a mass-market retailer.

- You are developing a budget-friendly or entry-level product line as part of a “good-better-best” strategy.

- The cookware’s primary intended use is for non-acidic applications like boiling water, pasta, or stocks.

- You need to achieve a specific, aggressive price point to win a tender or secure a large volume order.

Investing in 304 steel leads to lower return rates, fewer customer complaints, enhanced brand loyalty, and the ability to command a premium price. The initial higher cost is an investment in long-term profitability and brand integrity.

Bonray Cookware

Crucial Note: If you choose 201 stainless steel, your choice of cookware manufacturer becomes paramount. A reputable partner like Bonray will use high-quality 201 material and advanced manufacturing techniques to maximize its performance and lifespan, ensuring you still deliver a reliable product.

How a Trusted Manufacturer Partner Makes a Difference

Regardless of your material choice, your OEM partner’s expertise is what turns raw steel into a quality product.

- Transparency is Key: A reliable manufacturer will provide material composition certificates upon request, guaranteeing that the 304 is truly 18/8 and the 201 meets quality specifications. At Bonray, we believe in full supply chain transparency.

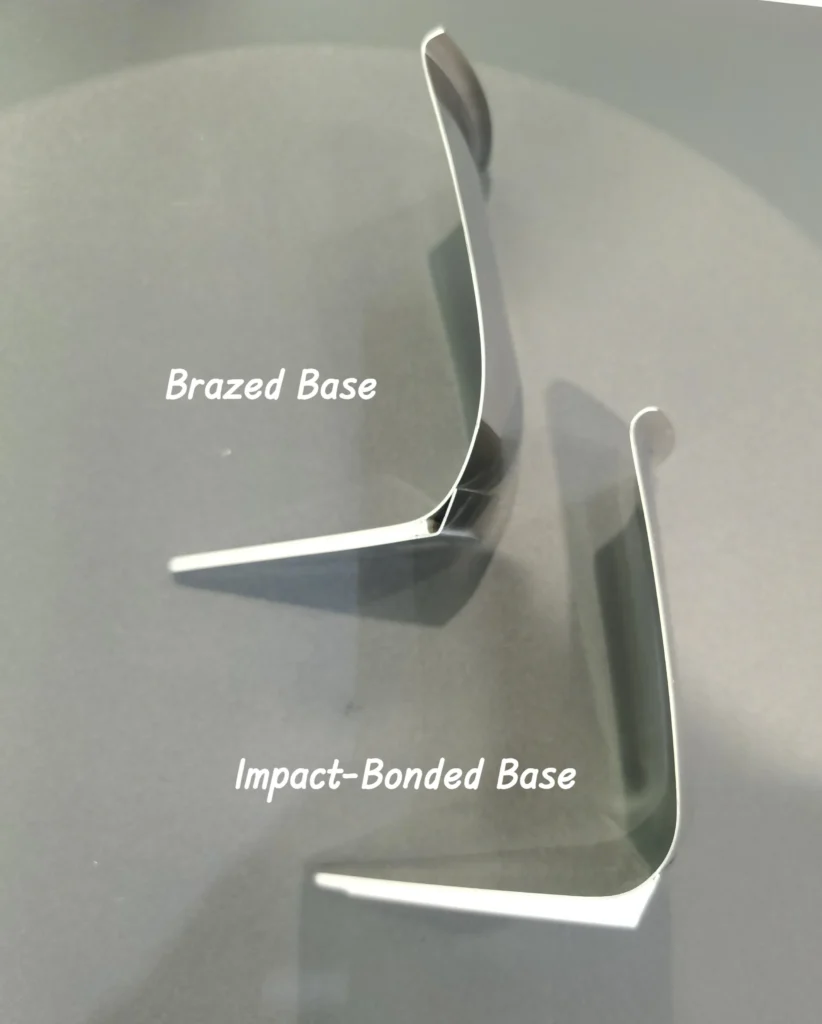

- Manufacturing Expertise: The final quality isn’t just in the steel—it’s in the welding, polishing, and construction of the base (e.g., tri-ply vs. encapsulated). We have extensive experience in optimizing the manufacturing process for both 304 and 201 steel to bring out the best in each.

- A Consultative Approach: We are more than just an order-taker. As your OEM partner, we will discuss your market goals, target price, and brand vision to help you make a strategic decision that benefits your business for years to come.

Conclusion: It’s Not “Better” vs. “Worse,” It’s About “Right Fit”

To summarize, 304 stainless steel is the undisputed choice for performance, durability, and premium brand positioning. 201 stainless steel is a viable, cost-effective alternative for specific markets and product strategies.

The most successful cookware brands understand this trade-off intimately. They don’t just sell a pot; they sell a promise. Aligning your material choice with that promise is the foundation of success.

Ready to discuss which stainless steel option is the perfect fit for your next cookware project? The Bonray team is here to help.

Watch Bonray’s Cookware Production Process:

Frequently Asked Questions (FAQ)

1. Is 201 stainless steel good for cookware?

Yes, 201 stainless steel can be a good, cost-effective choice for certain types of cookware. It is best suited for applications like boiling water, pasta, or stocks where exposure to high acid or salt is minimal. While it is less corrosion-resistant than 304 steel, its primary advantage is affordability, making it ideal for budget-friendly product lines. The final quality and longevity of 201 cookware heavily depend on the manufacturer’s production and finishing processes.

2. What is the best grade of stainless steel for cookware?

For all-around performance, durability, and safety, 304 stainless steel (also known as 18/8 or 18/10) is widely considered the best and most common grade for high-quality cookware. Its high nickel content offers superior resistance to rust and corrosion from all types of foods, including acidic ones like tomato sauce. This makes it the standard choice for premium and professional brands that prioritize longevity and unwavering customer trust.

3. How can you tell the difference between 304 and 201 stainless steel?

Visually, it is nearly impossible to tell the difference between 304 and 201 steel without testing. The most reliable methods involve a chemical spot test or using an X-ray fluorescence (XRF) analyzer for a precise composition breakdown. As a buyer, the most secure way to guarantee you are receiving the correct material is to partner with a transparent manufacturer who can provide an official Material Test Certificate (MTC) for your specific production batch.

4. Is 201 stainless steel food safe?

Yes, 201 stainless steel is generally recognized as safe for food contact. It is widely used for food preparation equipment and many types of cookware. However, because it has lower corrosion resistance than 304, there is a small risk of pitting or rusting if it’s in prolonged contact with highly acidic or salty foods. For guaranteed non-reactivity across all cooking conditions, 304 stainless steel remains the industry’s preferred food-grade material.