Case Study

Custom Stainless Steel Grill Pan for a Kitchenware Distributor

Custom Stainless Steel Grill Pan Project Background

A European wholesaler and distributor of home and kitchenware products approached our team with a request for a custom grill pan solution to add to their cookware lineup. The project involved manufacturing two variations of a stainless steel grill pan based on the client’s technical drawings and measurements.

As a kitchenware manufacturer experienced in OEM projects, we understood the importance of meeting the exact specifications and quality standards for this custom order.

Project Overview

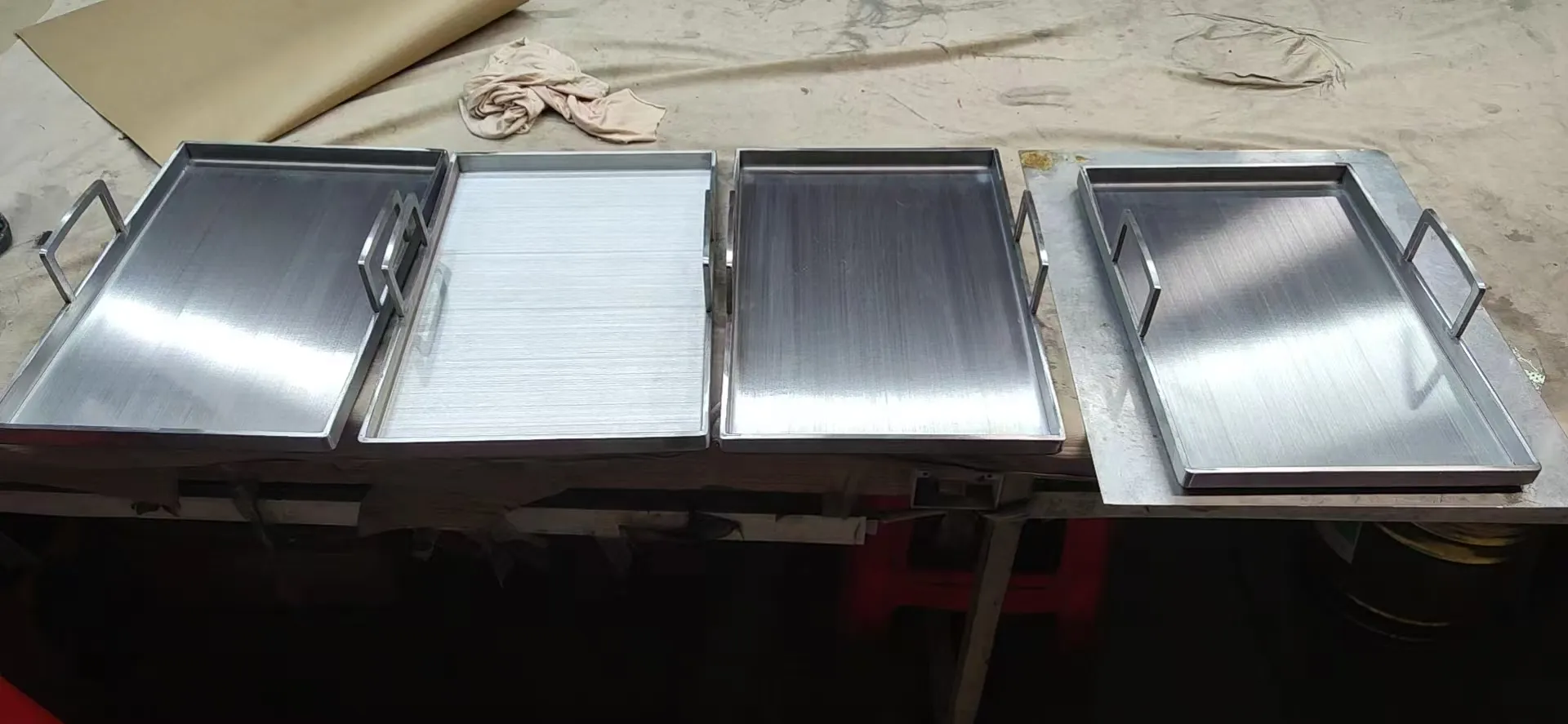

The project involved creating two variants of a grill pan based on the client’s technical drawings: one design featured four raised sides (forming a shallow tray), and the other had open sides on two ends. Both versions were constructed in stainless steel with dual handles. This case study details how we engineered these pans with precision welding, a brushed satin finish, and iterative prototyping to ensure top quality and performance.

Two Design Variants: Developed a four-sided grill pan (four welded corners) and an open-sided griddle-style pan (two welded corners) using the same production process.

Corner Options: Offered both straight-edge corners for a crisp look and rounded corners for safer handling, achieved through post-weld grinding.

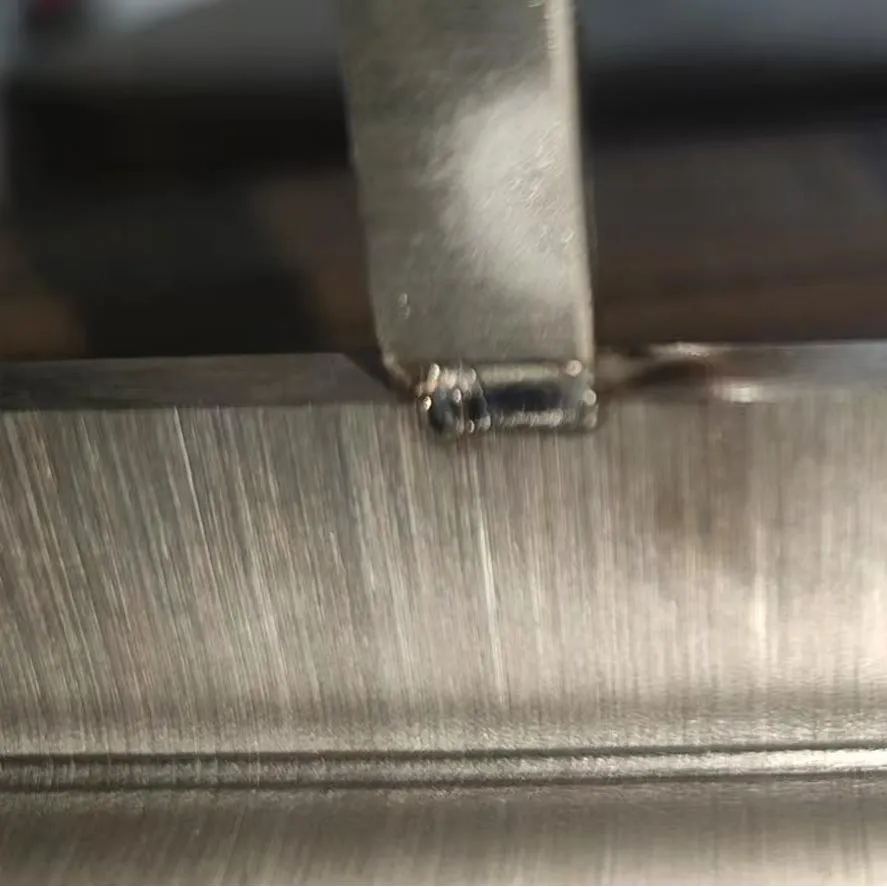

Precision Welding: Employed laser welding for corner seams (minimal weld marks, leak-proof joints) and TIG (argon arc) welding for handle attachment (strong, clean welds).

Brushed Satin Finish: Achieved a uniform brushed stainless steel finish on all surfaces, with weld areas polished to blend seamlessly.

Prototyping Improvements: Identified and corrected thermal warping by introducing a slightly curved base in the design.

Successful Outcome: Delivered a durable, high-quality grill pan line. The client was highly satisfied and reported improved product sales after launch.

This set of requirements laid the groundwork for a challenging but rewarding manufacturing project. The thick stainless steel and the dual design variation meant we needed to carefully plan the fabrication process to ensure consistency and functionality.

The client provided detailed drawings and dimensions for two grill pan styles. The first style was a rectangular pan with four raised sides, essentially forming a flat-bottomed tray. The second style had three raised sides, with the back edges open. This meant the four-sided pan required welding at four corners, whereas the open-ended pan needed only two corner welds.

Despite the difference in corner count, we planned the same fabrication process for both variants, ensuring consistency in quality and appearance.

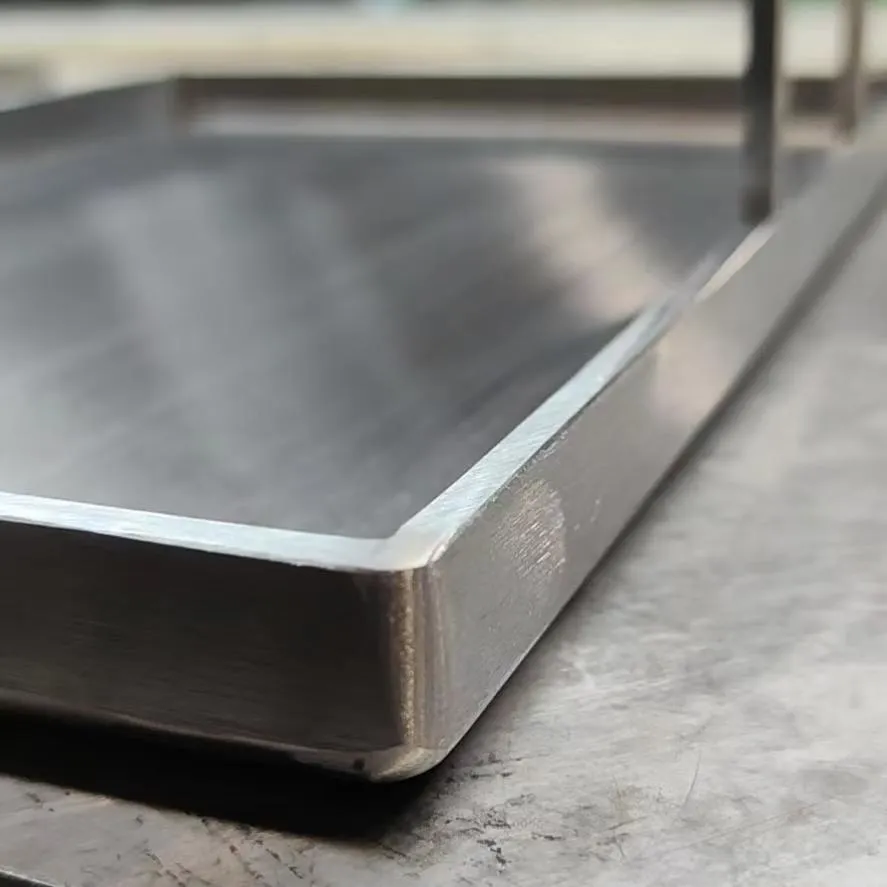

Stainless Steel Grill Pan with Rounded Edge

Grill Pan with Straight Edge

Stainless Steel Grill Pan with Rounded Edge

Design & Engineering Solutions

One early design decision involved how to form the corners of the raised-edge grill pan.

Each pan could be built with straight corners or rounded corners based on the distributor’s preference. Straight corners have a clean, squared-off aesthetic but could be relatively sharper to the touch; rounded corners, by contrast, are smoother and safer to handle. Different corner effects are decided by different post-welding process: if rounded corners were desired, extra grinding was done at the corners to create a gentle radius. In either case, careful finishing would remove any burrs or sharp edges while meeting the visual design intent.

The client selected the rounded corner solution, which offered aesthetic appeal and provide a smooth, safer edge that reduces the risk of scraping or cutting when handling the pan.

The custom stainless steel grill pan with four raised sides and dual handles (closed design). Both requested designs shared identical manufacturing processes despite differences in the number of sides.

In terms of dimensions and material, both versions used high-grade stainless steel sheets cut and formed to shape. The base thickness and side heights were specified by the client to balance sturdiness with weight. Our engineering team reviewed the drawings and confirmed that the design was feasible for fabrication without any major modifications. This upfront collaboration ensured that from the simplest two-corner pan to the fully enclosed four-corner pan, we could apply the same welding and finishing techniques for uniform results.

Precision Welding & Assembly

Challenges

During the custom grill pan manufacturing, we have to allow the thick 3.0mm stainless steel to be joined cleanly with minimal heat distortion and keep the appearance appealed without weld marks.

In addition to the corners, the dual side handles were a focal point of the engineering process. As the client’s design called for wide, easy-to-grip handles on both sides of the pan, welding securely to the side walls is very important.

Solution

To solve the challenges during stainless steel fabrication, Bonray employed laser welding technology to join the stainless steel panels at the corners. Laser welding allowed us to make precise, high-energy weld seams with minimal heat-affected zone. This resulted in clean, smooth corner joints with very little distortion or discoloration.

All corner seams—whether two or four—were fused using this method, creating virtually seamless edges. The welds were so fine that after a bit of finishing (grinding and brushing), the weld lines were barely visible and the corners appeared as if formed from a single piece of steel. Each welded corner was also leak-tested by filling the pan with water to ensure there were no pinholes or gaps; the laser welds held perfectly, guaranteeing that the four-sided pan could contain liquids or oils without any leaks.

Attaching the handles was the next crucial step. Each grill pan featured two robust handles, one on each side, to allow for safe carrying and maneuvering. For handle attachment, we chose TIG (argon arc) welding. TIG welding is known for its precision and is ideal when you need strong welds that also look visually neat.

Using argon shielding gas, our welders carefully TIG-welded each handle onto the pan’s side walls. This process yielded durable, load-bearing joints with a smooth, polished appearance, aligning with the high-end look of the product. The heat input was controlled to avoid warping the side walls while ensuring the handles were firmly affixed. After welding, any minor weld beads around the handles were ground down, and the area was polished so the handle joints transitioned cleanly into the pan’s body. The result was not only functional (the handles could easily support the pan’s weight with food) but also aesthetically refined – an important factor for a product that would be visible to consumers.

Results

Bonray’s manufacturing process for the corners ensured that the joints were not only strong but also clean in appearance—an essential detail in premium cookware manufacturing.

By the end of the engineering phase, Bonray had refined the design for manufacturability without compromising the premium look or performance specified by the client.

Surface Finishing & Quality Assurance

Challenges

The finishing process was another critical step. The client had requested a brushed surface on both the top of the grill pan and the sides, a detail that would enhance the product’s commercial appeal.

Solution

After welding and assembly, all surfaces of the grill pans underwent an extensive finishing process. We applied a brushed satin finish across the interior and exterior surfaces, including the sides and corners. This finish involved grinding and brushing the stainless steel with fine abrasives to produce a uniform grain texture.

Crucially, the areas that had been welded (corner seams and handle joints) received special attention during finishing. We ground down any excess weld material and polished those sections so they blended in with the surrounding metal. The goal was to make the welds almost imperceptible both to the eye and touch.

One of our key priorities was to clean the weld seams thoroughly so that the final product didn’t carry any heat marks, burrs, or discoloration from the welding process. This attention to detail is what separates an average product from a professionally engineered one.

By the end of this process, the pans had a consistent texture and color throughout – you couldn’t readily tell where the pieces had been joined. This level of finish demonstrated the manufacturer’s strength in stainless steel fabrication: even with multiple welds, the final product looked like a single integrated piece.

Results

The result was a sleek, brushed stainless steel pan with no sharp edges or visible seams, meeting both the functional and aesthetic expectations. Each pan underwent visual inspection to ensure the finish was consistent and free of blemishes.

Thermal Testing & Base Refinement

Challenges

While the first prototype met all structural and aesthetic requirements, the client conducted internal testing and came back with an unexpected concern. During heat tests, they noticed that the pan’s bottom had a tendency to warp or bulge slightly under high temperatures. This was surprising, given the 3.0mm thickness. However, after analyzing the results, we concluded that the flatness of the bottom surface, combined with high thermal stress, was creating upward pressure during heating.

Solution

Instead of treating this as a problem, we saw it as an opportunity to refine the design even further.

Our engineering team implemented a curved-bottom design adjustment. We introduced a slight convex curvature to the base of the pan (barely visible to the eye) so that when the metal heats up and expands, the pan bottom flattens out rather than arching. This design refinement was tested and proved successful – under thermal testing, the modified pans maintained a flat, stable base. We adjusted the tooling accordingly and produced a new prototype with the modified base design.

Results

After several rounds of high-temperature testing, the issue was completely resolved. The pan remained stable, evenly heated, and visually unaffected—even after prolonged thermal exposure.

This prototyping cycle underscored our commitment to functional testing and refinement. Rather than proceeding to mass production with a potential flaw, we took the time to adjust the design and validate the performance. The client was kept informed during this process and appreciated the proactive approach. Ultimately, this iterative improvement meant that the final grill pans would perform reliably in the hands of end-users, maintaining even contact with grill tops or stovetops without rocking. It’s a prime example of our strength in prototyping – using real-world testing to catch issues and optimize the product before full-scale manufacturing.

Conclusion

After incorporating the design improvements, we moved into final production. The batch of custom grill pans was completed to specification and passed all quality checks. The client was very pleased with the outcome, noting the robust build and premium look of the pans. The precision welding, quality of the finish, and thorough functional testing distinguished our manufacturing process and gave the client confidence in the product’s durability and performance.

The product launch was smooth – the grill pans fit perfectly in the client’s existing product range and branding. The customer satisfaction was evident not only in the client’s positive feedback to our team, but also in the market response.

The distributor reported improved sales in their cookware category after adding the custom stainless steel grill pans to their lineup, as customers were drawn to the pans’ solid construction and design features. The success of this project has strengthened our partnership with the client, and we continue to serve as their go-to OEM cookware manufacturer for new product ideas.

Ready to bring your custom cookware idea to life?

Related Custom Projects

Start Your Custom Cookware Project

Looking for a reliable partner to manufacture custom stainless steel cookware at scale? Whether you need OEM grill pans, saucepans, stockpots, or a full line of cookware, our factory is ready to support your brand with precision fabrication, fast lead times, and flexible solutions tailored to your market.

- 98% On-Time Delivery Rate

- <0.5% Product Defect Rate

- Custom Solutions Delivered to 30+ Countries